Sila Nanotechnologies’ battery technology will launch in Whoop wearables - 5 minutes read

Sila Nanotechnologies next-generation battery technology made its commercial product debut Wednesday in the new Whoop fitness tracker, a milestone that caps a decade of research and development by the Silicon Valley startup all aimed at cracking the code to packing more energy into a cell at a lower cost.

Billions have been spent over the past few years on improving battery chemistry, with different startups aiming to either replace the anode or the cathode with a conversion material, like silicon or even lithium in the case of solid state companies.

Sila Nano’s battery chemistry recipe replaces graphite in a battery cell’s anode with silicon to create a more energy-dense and cheaper battery pack. Other companies, like BASF are focusing on creating a high energy dense cathode.

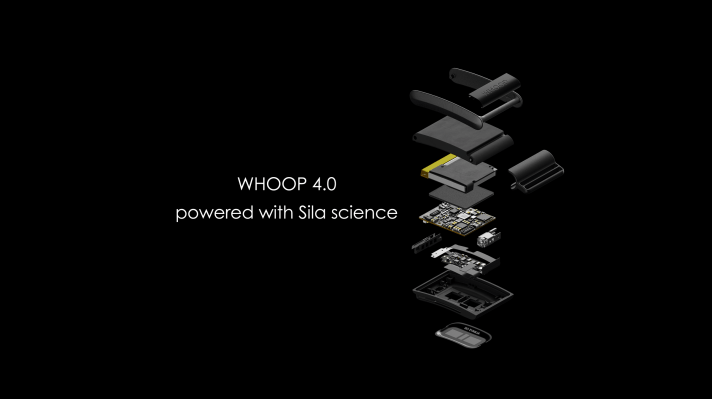

While numerous companies are working on a variety of different battery chemistries, they have yet to take over the traditional cell technology found in today’s lithium-ion cells. The Sila battery used in the upcoming Whoop 4.0, the company’s latest health and performance tracker, could be the first time in the last few decades the world has seen a next-generation battery chemistry ship to market.

“Launching a small fitness tracker doesn’t seem like a big thing, but this is really the first device in the market that proves our breakthrough, and over time, this will scale and lead to the electrification of everything,” Gene Berdichevsky, founder and CEO of Sila Nano, told TechCrunch.

Electric vehicles, and Sila Nano’s role in powering them, is at the top of Berdichevsky’s “electrification of everything” list. And the company has already made headway.

Sila Nano has joint battery ventures with BMW and Daimler to produce batteries containing the company’s silicon-anode technology, with the goal of going to market in the automotive industry by 2025.

“You can translate this success with Whoop to cars in many ways,” said Berdichevksy. “Today, if you want a really long range vehicle, it better be a pretty big car. The smaller the EV, the shorter the range because there’s nowhere to put the battery. But as our technology advances into the automotive market, you’ll be able to have a city car that has 400 miles of range on it. This is enabling more segments of the auto industry to electrify.”

Whoop, which earlier this month announced a $200 million raise at a $3.6 billion valuation, is introducing the Whoop 4.0 as a wearable that’s 33% smaller, in large part as a result of Sila’s battery, which has about 17% higher energy density, according to Berdichevsky. Not only does a denser, better battery lead to a smaller wearable, but Whoop was able to add additional features – like a sleep coach with haptic alerts, a pulse oximeter, a skin temperature sensor and a health monitor – without compromising its five-day battery life.

“One of the key outcomes of enabling a chemistry like ours is it allows you to build things that couldn’t otherwise be built,” said Berdichevsky.

In Whoop’s case, that’s referring to its new Any-Wear tech that allows the wearable to be integrated into a new line of garments like bands that can collect sensor data from areas including the torso, waist and calf.

It’s not just Sila’s chemistry that’s allowing for a successful product to go to market. It’s the scalability of the product that’s really important. Scalability has been built into Sila’s roadmap from the beginning.

“One of the things we did very early on is we told our scientists and engineers they could only use global commodity inputs so that we know we can make enough for millions of cars,” said Berdichevsky. “Next we said you had to use only what we call ‘bulk manufacturing’ techniques, and that means you use volumetric reactors rather than planar reactors.”

An easy way to think about the difference in reactor types is through the analogy of making enough food to feed a crowd: A big pot of chili (the volumetric reactor) will go a lot farther than individual pizza pies (planar reactors).

Berdichevsky also told his team that anything they created had to be able to seamlessly drop into any battery factory process, whether that factory is supplying batteries for smartphones, cars or drones.

Sila Nano has already proven scalability twice, Berdichevsky said. The first time it scaled 100x from lab to pilot, starting with volumetric reactors that were about the size of a liter. Wednesday’s partnership with Whoop marks the second time the company has scaled up 100x, and this time to 5,000 liter reactors. To put that in relative terms, a couple of humans could probably climb into one of those reactors. The next stage of scaling will involve reactors large enough that you could drive a car through, says Berdichevsky, which is fitting given Sila Nano’s goal of scaling up to automotive quantities over the next three years.

“The reason we’re not in cars today is we have to go scale up 100x to have enough to really deploy in cars, but the material is the same,” said Berdichevsky. “The particles, the powder we make, it’s the same in every one of the scales we’ve made so far.”

Source: TechCrunch

Powered by NewsAPI.org