NASA’s technology program funds ambitious in-space manufacturing mission - 4 minutes read

NASA seeks to break the “tyranny of launch” with in-space manufacturing

NASA seeks to break the “tyranny of launch” with in-space manufacturingMade in Space is one of the most intriguing companies in aerospace because they're not so much focused on getting into space. Rather, the company is focused on doing interesting, meaningful, and potentially profitable things once there. Its long-term goal is to build factories in space using additive manufacturing.

A recent NASA contract, worth $73.7 million, will allow Made in Space to significantly accelerate those efforts. "For us, this is one of those watershed moments that take this technology and propel it into the next stage," said Andrew Rush, president and chief executive officer, in an interview with Ars. Made in Space started the year with 40 employees, and will end it with nearly 100.

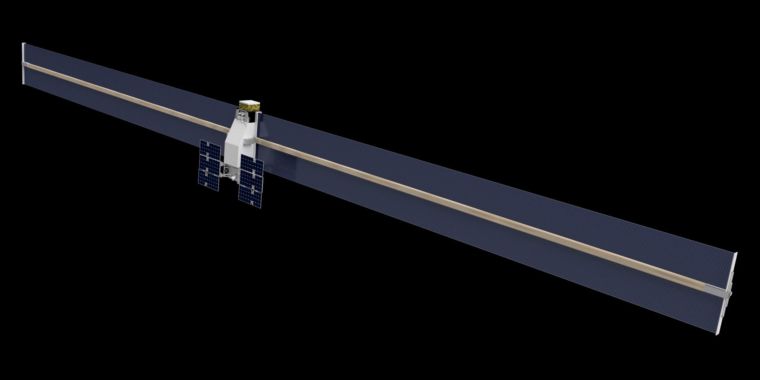

The NASA contract will fund the company to build and fly a spacecraft it calls Archinaut One, with the aim of constructing two 10-meter solar arrays in orbit. These two arrays will power an ESPA-class satellite. (These are fairly small satellites, about 200kg, that are typically carried as secondary payloads by large rockets such as the Falcon 9 booster built by SpaceX.)

The basic idea is that, if Archinaut One can manufacture its own solar arrays in space—rather than having to fold them in a cumbersome way inside a payload fairing—they can be much larger than those on a typical ESPA-class satellite. Instead of a few hundred watts of power, therefore, a small satellite might be able to have as much as five to eight times that amount to work with.

Typically, such power capabilities have only been available on much larger satellites flying in geostationary space. More electricity will allow satellite operates to use much significantly more powerful sensors, on-board computing, and more, Rush said.

Made in Space has already performed some ground-based demonstrations of the Archinaut technology, which manufactures a central spar, onto which rolled up solar arrays can be extended and locked into place. The NASA funding will allow Made in Space to build the spacecraft, test it on the ground, and then fly it into space. The company is targeting a 2022 launch on an Electron booster built by Rocket Lab.

NASA funded the demonstration mission through its Space Technology Mission Directorate. This part of NASA, which is distinct from the agency's other programs, funds the kinds of breakthrough technologies that may not be of immediate use, but are the seed corn for cutting edge exploration in one or two decades.

“In-space robotic manufacturing and assembly are unquestionable game-changers and fundamental capabilities for future space exploration,” said Jim Reuter, associate administrator of NASA’s Space Technology Mission Directorate. “By taking the lead in the development of this transformative technology, the United States will maintain its leadership in space exploration as we push forward with astronauts to the Moon and then on to Mars.”

For Made in Space, this is an important step toward breaking the "tyranny of launch," by which every mission that leaves Earth is constrained by its dimensions, including size, mass, and its ability to survive the dynamic forces of launch. By manufacturing satellite components in space, the company hopes to unfetter some of those launch constraints.

Source: Ars Technica

Powered by NewsAPI.org

Keywords:

NASA • Tyrant • Space manufacturing • Made In Space, Inc. • Company • Aerospace engineering • Company • Profit (economics) • Object (philosophy) • Goal • 3D printing • NASA • Made In Space, Inc. • Drainage divide • Technology • Chief executive officer • Made In Space, Inc. • NASA • Spacecraft • Photovoltaic system • Low Earth orbit • Self-control • Small satellite • Payload • Rocket • Falcon 9 • Booster (rocketry) • SpaceX • Solar panel • Payload fairing • Electricity • Satellite • Geostationary orbit • Electricity • Satellite • Sensor • Computer • Made In Space, Inc. • Earth • Technology • Spar (aeronautics) • Photovoltaic system • NASA • Made In Space, Inc. • Spacecraft • Earth • Flight • Space launch • Electron • Booster (rocketry) • Rocket Lab • NASA • Technology demonstration • Outline of space technology • NASA • Technology • Maize • Robotics • Manufacturing • Manufacturing • Basic research • Future • Space exploration • Public administration • NASA • Outline of space technology • United States • Space exploration • Astronaut • Moon • Mars • Made In Space, Inc. • Space launch • Earth • Dimension • Volume • Mass • Space launch • Satellite • System • Space • Space launch •